Subtotal ₹0.00

- Home

- Pages

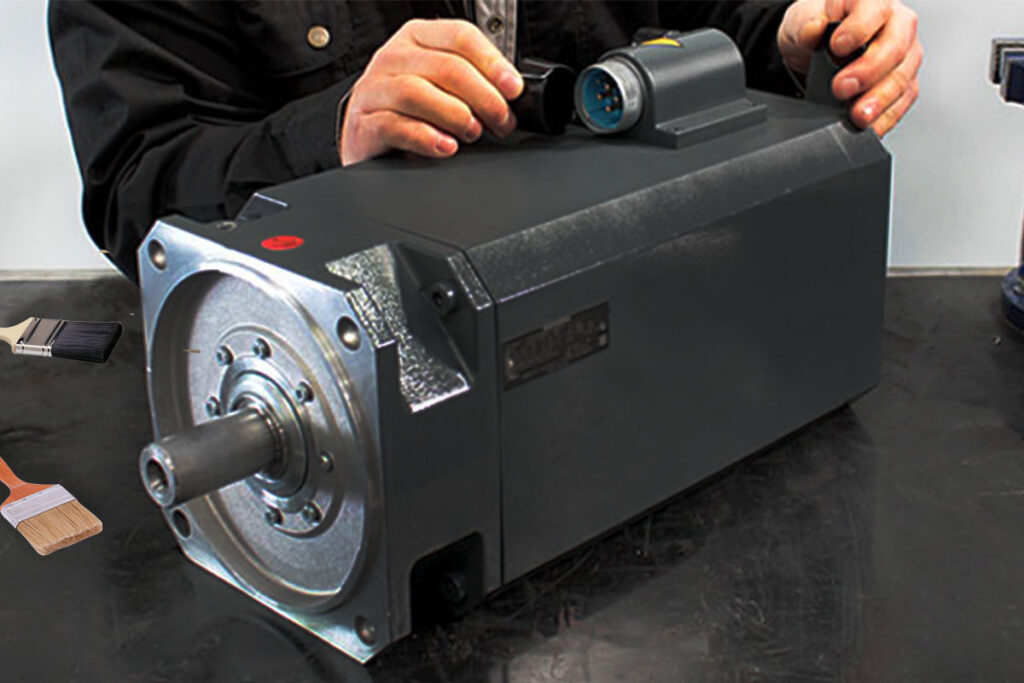

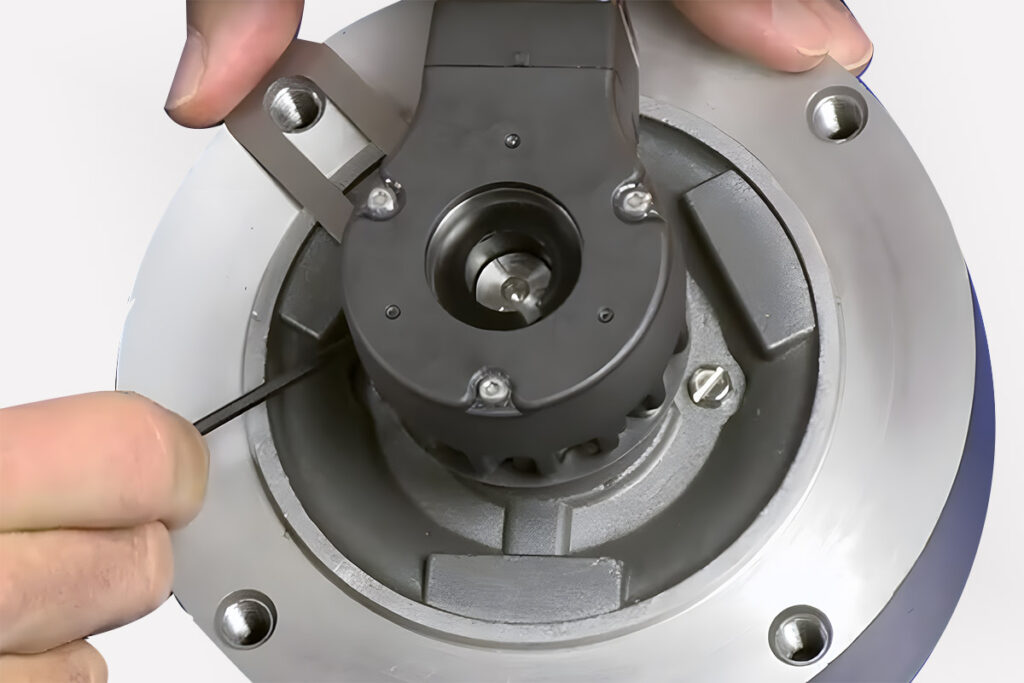

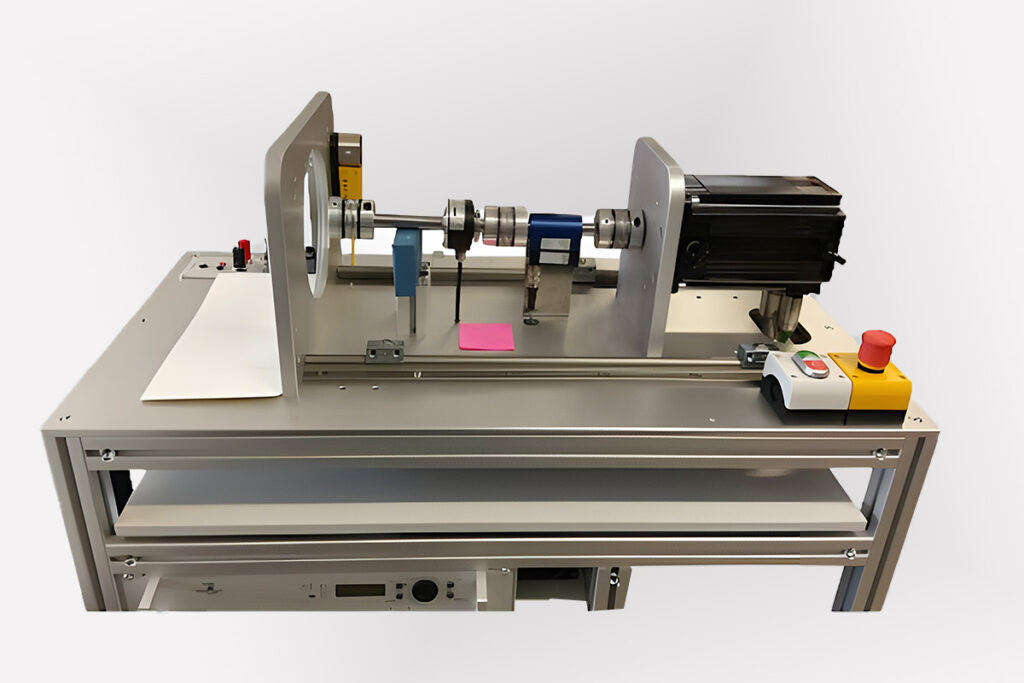

- Servo Motor Repair

- Categories

- Servo Motor

- HMI

- Power SuppliesWith our extensive skills and experience, we are equipped to tackle any challenges related to your power unit, including switch mode, linear, regenerative, single-output, multi-rail, uninterruptible, or phase-sensitive power supplies.

- PLCStar automations recognizes the growing dependence on PLC systems and offers top-notch, affordable repair services for a wide array of products, such as Interface Modules, Communication Modules, I/O Modules, Processors, Power Supplies, and entire PLC racks.

- DrivesOur established inverter team routinely repairs AC variable speed Drives from 0.37kw up to 500kw and above. We also repair DC Drives from 0.5kw to over 300kw. We have the capabilities to repair all types of industrial drives including: • AC drives • DC drives • Servo drives • Spindle drives • Stepper drives

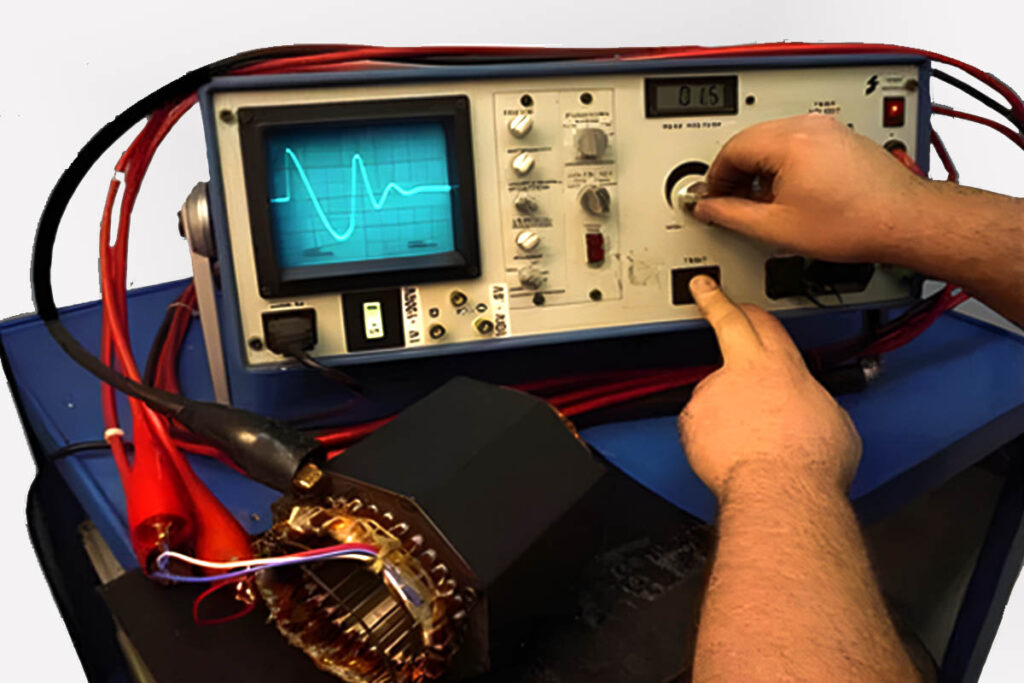

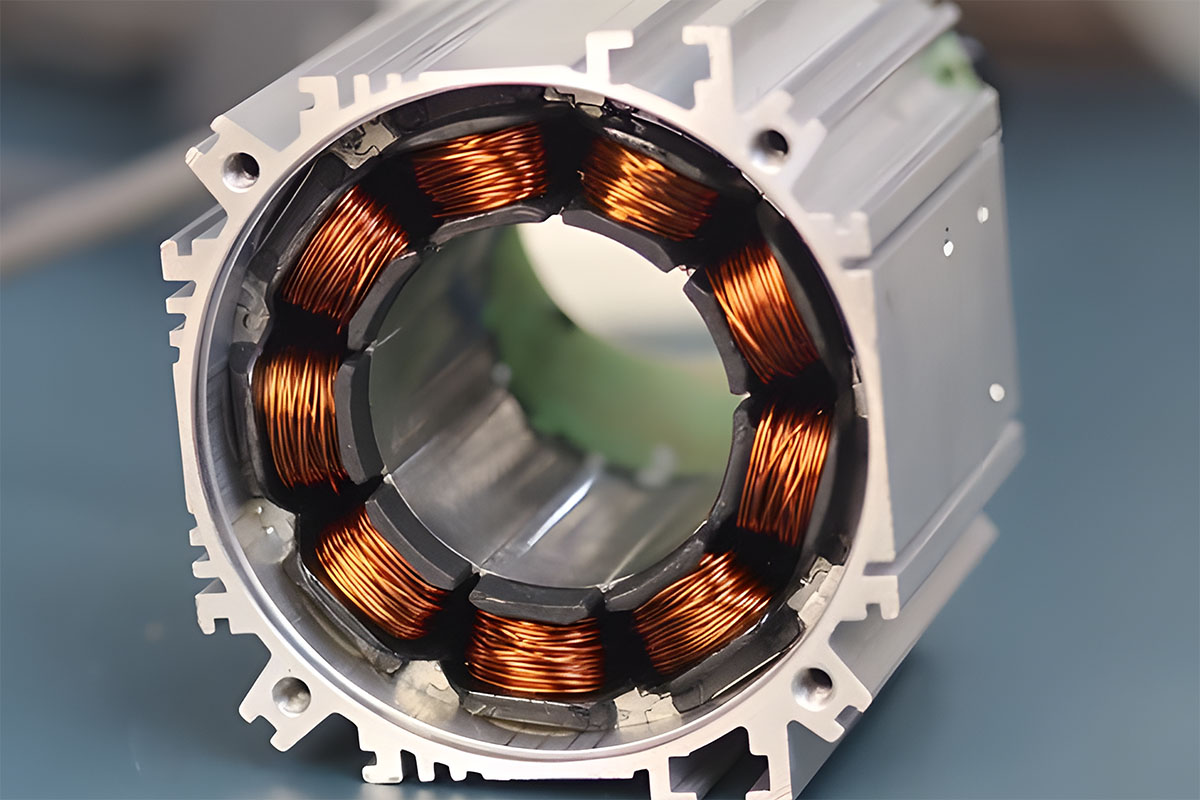

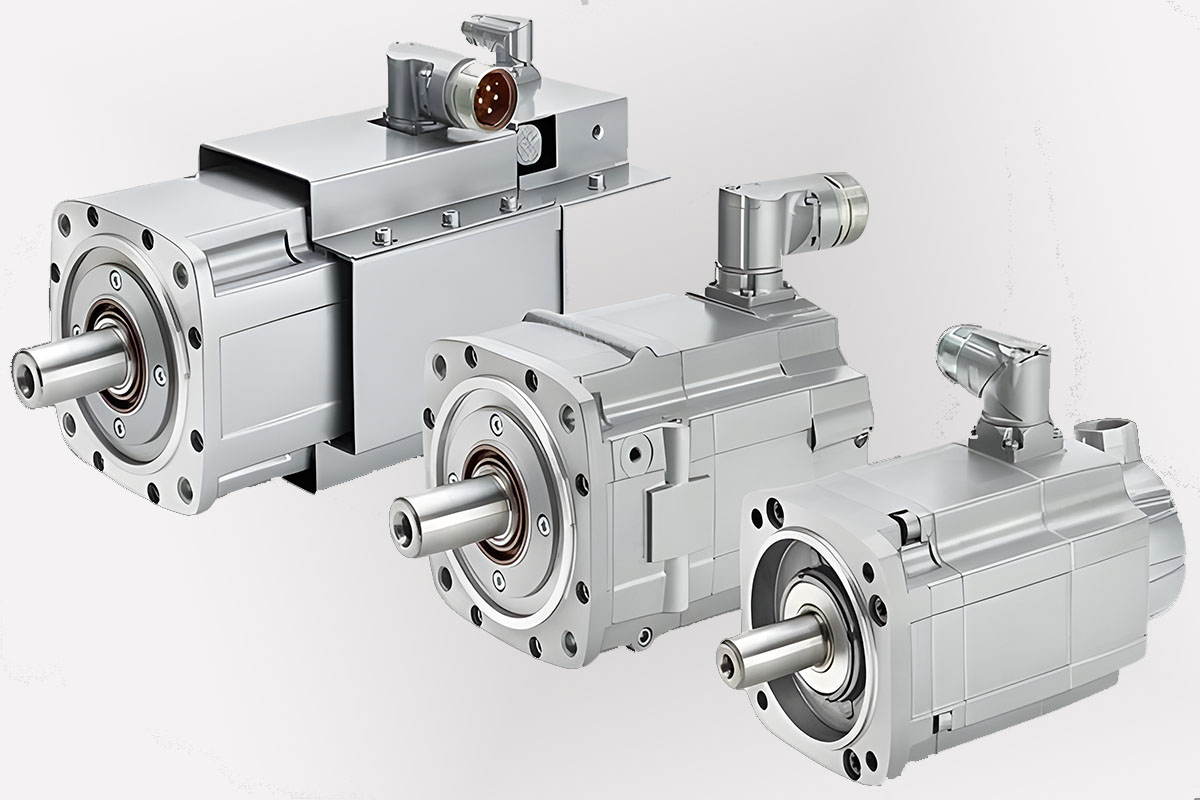

- MotorsStar Automations has a thorough understanding of how servo motors work with machine tool servo systems. A wide variety of motors, including AC, DC, Servo, stepper, and slip ring motors, are among the many types of motors we supply and repair.

- Contact